Research Areas

The Bioprocess Development Lab at IIT Guwahati focuses on sustainable process development for value-added products using microbes as cell factories. Our research spans microalgae-based biofuel production, metabolic engineering for omega-3 fatty acids, bioprocess optimization for high-value compounds, and innovative waste-to-energy technologies. We combine chemical and biochemical engineering, systems biology, and molecular biology to address challenges in renewable energy, bioproducts, and environmental sustainability.

-

Microalgae-Based Biofuel ProductionSustainable processes for large-scale biocrude oil production via hydrothermal liquefaction of microalgae coupled with CO2 sequestration. Focus on synchronized cultivation, CO2-rich fuel gas utilization, and direct wet biomass conversion.

Microalgae-Based Biofuel ProductionSustainable processes for large-scale biocrude oil production via hydrothermal liquefaction of microalgae coupled with CO2 sequestration. Focus on synchronized cultivation, CO2-rich fuel gas utilization, and direct wet biomass conversion.- Optimization of microalgae cultivation parameters

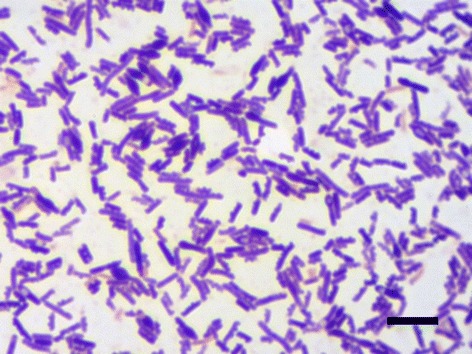

- Carbon sequestration for the production of biomaterials through chemoautotrophs, methanotrophs

- Process engineering for hydrothermal liquefaction

- Economic analysis of biocrude oil systems

-

Omega-3 Fatty Acid ProductionOptimization of docosahexaenoic acid (DHA) and eicosapentaenoic acid (EPA) production in heterotrophic microalgae (e.g., Schizochytrium sp.) using metabolic engineering for nutraceutical and pharmaceutical applications.

Omega-3 Fatty Acid ProductionOptimization of docosahexaenoic acid (DHA) and eicosapentaenoic acid (EPA) production in heterotrophic microalgae (e.g., Schizochytrium sp.) using metabolic engineering for nutraceutical and pharmaceutical applications.- High DHA/EPA yield via cultivation optimization

- Metabolic engineering for enhanced production

- Downstream processing development

- Scale-up for industrial application

-

Bioprocess Development for Valuable CompoundsEfficient bioprocesses for high-value microbial products such as C-phycocyanin, biomaterials, and recombinant antibody fragments. Focus on fermentation optimization, bioreactor design, and sustainable downstream processing for industrial applications.

Bioprocess Development for Valuable CompoundsEfficient bioprocesses for high-value microbial products such as C-phycocyanin, biomaterials, and recombinant antibody fragments. Focus on fermentation optimization, bioreactor design, and sustainable downstream processing for industrial applications.- Fermentation parameters optimization

- Bioreactor design & scale-up

- Efficient downstream processing

- Techno-economic process integration

-

Waste-to-Energy Conversion TechnologiesInnovative conversion of agricultural, food, and industrial waste into energy products. Integration of biological and thermochemical methods for resource recovery and minimal environmental impact.

Waste-to-Energy Conversion TechnologiesInnovative conversion of agricultural, food, and industrial waste into energy products. Integration of biological and thermochemical methods for resource recovery and minimal environmental impact.- Waste feedstock characterization

- Pretreatment method development

- Conversion process optimization

- Life cycle assessment of systems