Microstructural modeling of materials:

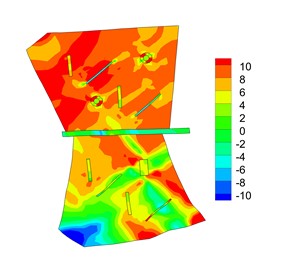

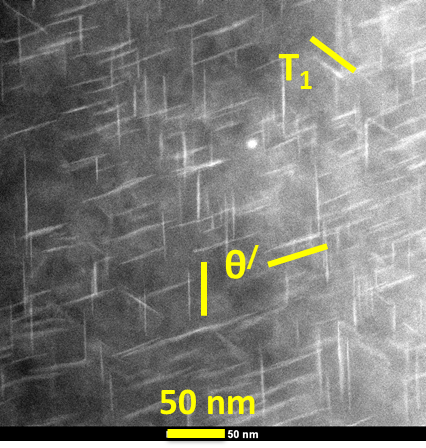

Processing of metallic alloy needs knowledge of materials microstructure. Precipitates, dispersed particles and inclusions play important roles in strengthening, toughening, and even in failure of materials. Microstructure of these materials can be tailored to have better thermo-mechanical properties. Experimental characterization cannot give a complete understanding, and hence, computational modeling of materials microstructure is essential to develop new materials. Dislocation density based crystal plasticity modeling is proved to be very useful to get a reasonable prediction of materials behavior at different length scales.

Crystal Plasticity Finite Element modeling can be applied on wide variety of most commonly used materials like aluminum alloys, steel, other important metallic alloys, and some advanced materials.

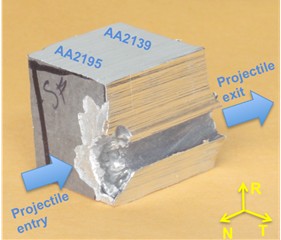

Modeling and characterization of materials at high strain rate loading:

Study of material deformation and failure under high strain rate loading is important in applications like armor, aerospace and automotive industries. Dynamic failure modes, specially shear strain localization and dynamic fracture, are recently considered as hot topics of research in mechanics of materials field. Both modeling and experiments are equally important to have a better insight of this field.

For prospective students:

Micromechanics of Materials Group is seeking for a PhD student to work on a project related to the following areas.