Shakshat Virtual Lab

INDIAN INSTITUTE OF TECHNOLOGY GUWAHATI

THEORY :

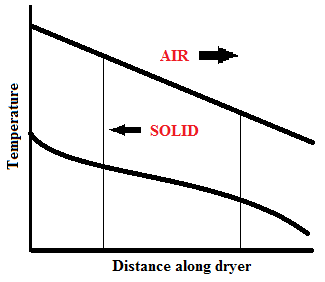

Consider a rotary continuous counter current dryer fed with a non - porous material having all moisture as unbound moisture. As the material enters the dryer , it is first heated to the drying temperature . It will then pass through the length of dryer at nearly the wet - bulb temperature and theoritically at the end of the dryer , the material shall be discharged as dry material nearly at the wet bulb temperature.

Experimental Procedure :

Set the pre - heating temperature for air .

Fill the feed hopper with wet solid.

Measure the initial moisture content of the feed.

Start the dryer in rotary motion.

Allow the wet solid to flow through the dryer by starting the screw conveyor at the pre fixed speed..

At steady state record the following :

Repeat the above steps for atleast 4 gas flow rates.

a) Air flow rate (Orificemeter, manometer reading and convert it to volumetric flow rate and mass flow rate ) = GG

b) Air temperature at inlet = tG1

Air temperature at outlet = tG2

Assumptions :

No heat loss from the dryer.

Heat is supplied only from the air, not by conduction from the dryer shell.

All the moisture present is free moisture.

There is no evaporation of moisture in the preliminary heating period.

Drying proceeds at a constant wet - bulb temperature until desired amount of water has been removed.

The animation below describes the process :