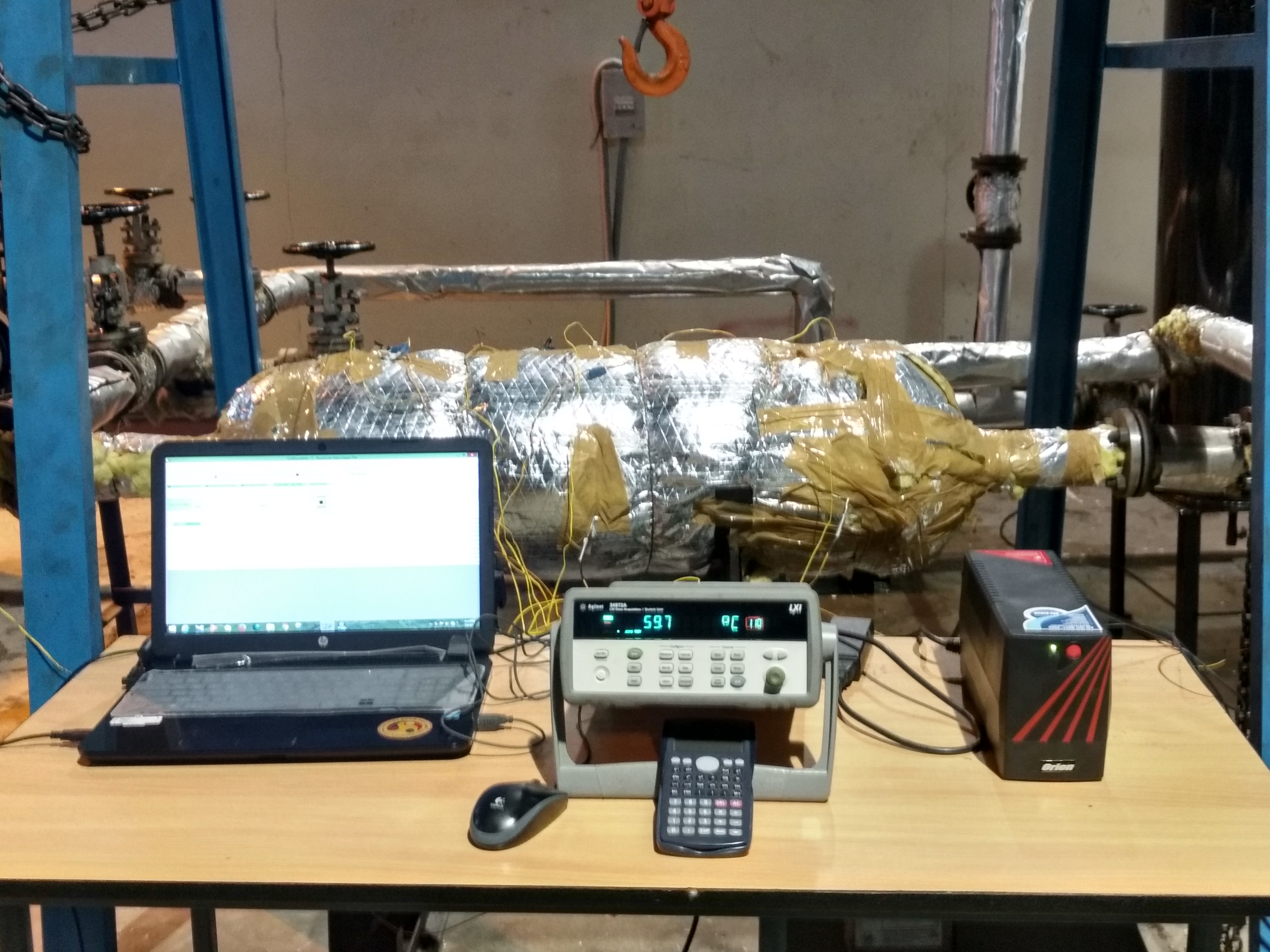

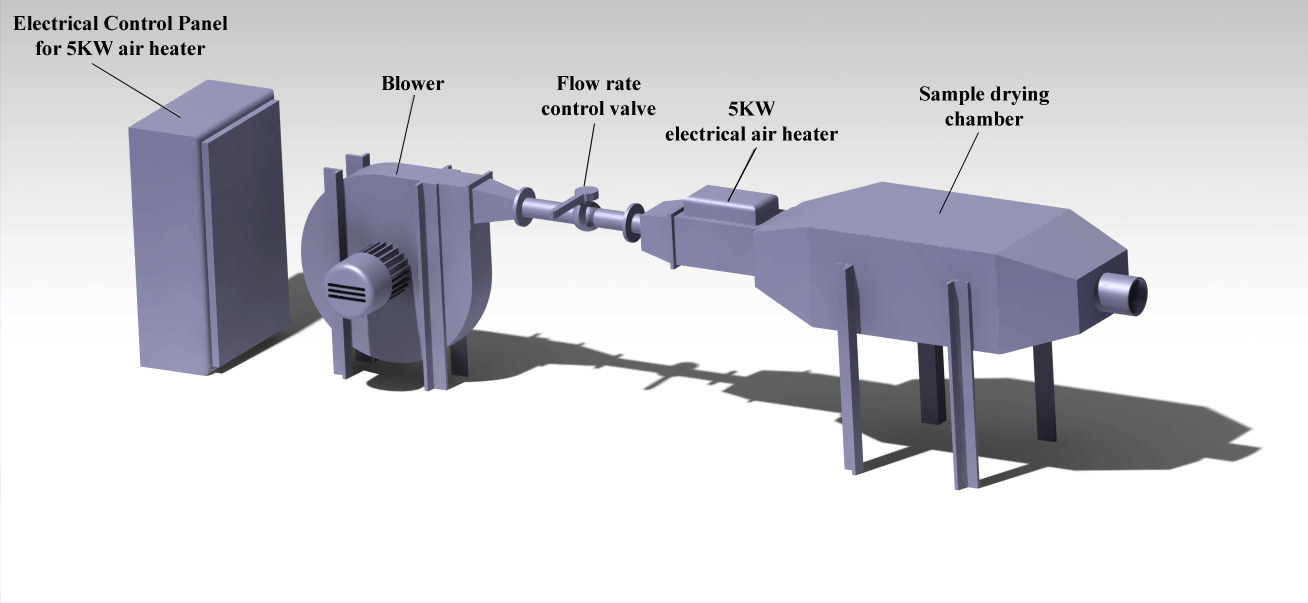

Experimental setup for testing energy storage models

up to 400 °C

Experimental setup for testing energy storage models

up to 200 °C

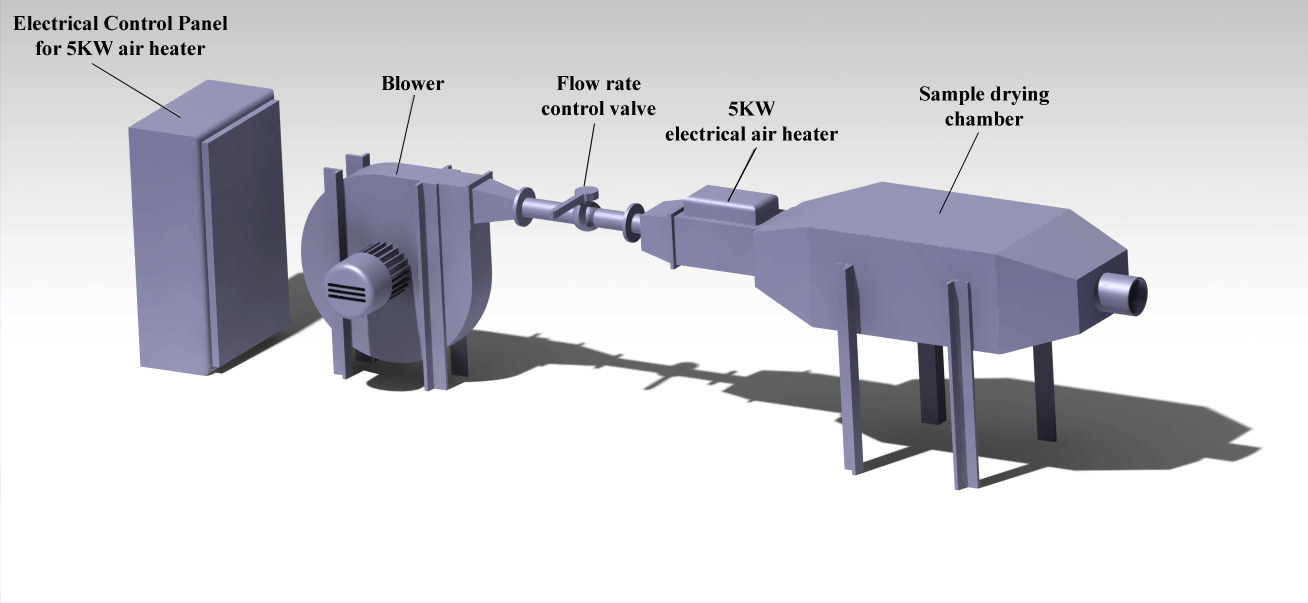

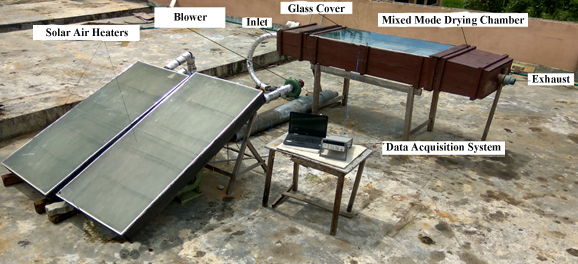

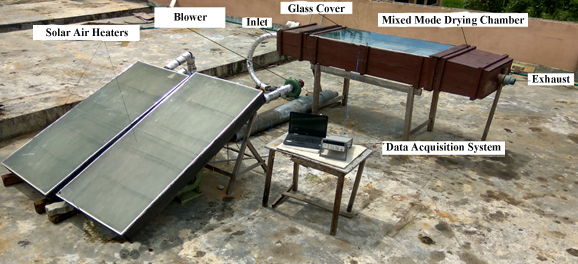

Schematic of Solar Dryer

Solar Dryer Experimental Set up developed at IIT

Guwahati

Previous

Next

Thermal Energy Storage

Thermal energy storage system (TESS)provides a great means to correct

the mismatch between the energy supply and demand. During on sun

hours, the excess thermal energy available is stored in TESS and the

stored energy is retrieved for producing electricity during off-sun

hours. The application of such systems range from low temperature

cooling systems to high temperature CSP technology.Thermal energy can

be stored in three different ways, viz., Sensible Heat Storage (SHS),

Latent Heat Storage (LHS) and Thermochemical Energy Storage (TCES).

In SHS system, thermal energy is stored in the storage material by

raising thetemperature. SHS utilizes the heat capacity of the storage

material to store the thermal energy. Materials such as Molten salt,

oil, rock, concrete, cast steel, etc. are used in SHS system.In LHS,

thermal energy is stored in the materials during the phase changeof

the material at a constant or near constant temperature.Salt hydrates,

Metals, Eutectics, Paraffin’s, etc. are employed as PCMs.

Our research team at IIT Guwahati possess a long-term experience

(past 10 years) in thermal modelling and testing of sensible and

latent heat thermal energy storage systems.

Focus:

- Development of thermal model for predicting the charging and

discharging characteristics of TESS (for both SHS and LHS)

- Design of heat exchanger that gives better heat transfer rate

- Experimentation of the energy storage models to evaluate actual

performance.

- Cyclic tests of the storage materials

An experimental setup was developed for testing lab scale storage

models. A synthetic thermic oil (Hi–Tech Therm 60) is used as heat

transfer fluid in this experimental setup. Both SHS and LHS models

were tested using this experimental setup. SHS materials such as

Concrete and Cast steel were tested on 10 MJ scale. Also, a 12 MJ LHS

model was developed using a ternary mixture comprising of potassium

nitrate, sodium nitrate and sodium nitrite in theweight proportion of

53:7:40, which has the melting point of approximately 142 °C.

Due to an increased interest in the field of renewable energy

particularly in solar energy, numerous thermal energy storage

materials have been identified and developed during the past few

years.Even though the improvements in terms of storage techniques are

remarkable, there is a need to develop a TESS that operates over 300

°C to make concentrating solar power technology cost competitive. The

current research at IIT Guwahati is aimed at developing and testing of

high temperature sensible, latent and thermochemical energy storage

models that operate over 300 °C. Anexperimental setup is developed

(shown in Fig. 2.) at IIT Guwahati for testing SHS and LHS models at

higher temperatures.

Thermochemical Energy Storage (TCES)

System:

Thermochemical heat storage (THS) systems rely on the energy absorbed

and released in

breaking and reforming molecular bonds of certain materials in a

completely reversible

chemical reaction. The utilisation of TCES materials offers a compact,

efficient and economic TESS. These systems provide higher energy

density, higher exergy efficiency and long term storage. At present,

our research team is focused on identifying potential TCES materials

and development of thermal model for predicting energy storage and

discharge characteristics. In future, characterization of the

potential TCES materials and preliminary experimental studies on lab

scale prototypes will be conducted.Hydroxides, carbonates and metal

hydrides are in major consideration.

Gallery

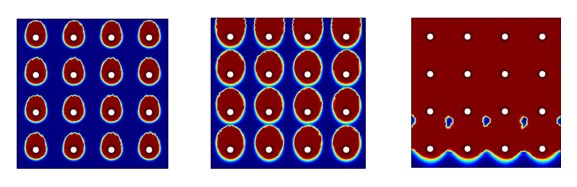

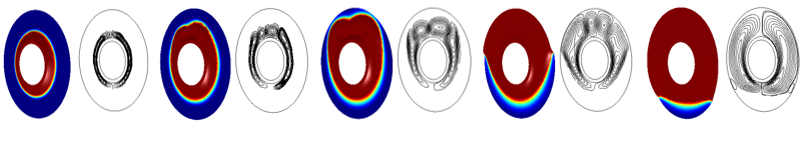

Modeling multi-tube heat exchanger

models

Storage module connected to a

charging/discharging cycle with temperature data

monitoring

Typical heat exchanger for

Cascaded TESS: 12 MJ capacity

Experimental setup for testing

energy storage models up to 200 °C

Natural Convection Phenomenon in

charging process of a storage system

Previous

Next

Solar Dryer

Solar dryers are devices that use solar energy or

radiation to dry substances, especially agricultural

products in order to preserve it. The solar dryer haveabsorbing

surface which absorb solar radiation and gain heat from

it.The heat energy is used to remove the moisture content from the

products, hence it dries up the product. There are three general

types of solar dryers: Direct, Indirect and Mixed mode.

Direct type solar dryer

Direct solar dryers expose the substance to be dehydrated in

direct sunlight. Here the product directly gain the heat

from sunlight and get dried. In this case there can be chances for

contamination of product by dust from wind, by birds, insects, or

animals.

Indirect mode solar dryer

In case of indirect type of solar dryer, air is heated separately

by using solar air heater and the hot dry (low % of Relative

Humidity) air is pass to the dryer chamber, where the product is

placed for drying. Here direct sunlight is not allowed to fall on

the product as,direct sun can chemically alter the contents of the

products and making them less appetizing.

Mixed mode solar dryer

In mixed mode dryer the solar radiation is allow to enter the

drying chamber to heat up the product inside the dryer and hot air

is also supplied to the drying chamber from separately connected

solar air heater. In this case the dryer receives heat from both

solar radiation and hot air, due to which the drying rate is faster

in mixed mode dryer.

The solar thermal lab at IIT Guwahati mainly focusses on the

following –

- Numerical and Experimental Studies to find the Drying Kinetics

of different products in all the three types of solar dryer.

- Trying to find out the optimum drying kinetics rate by varying

the air flow rates and incorporating PCM type thermal storage.

- Sampling of the dried product to find the best drying condition

for good quality of dried products.

Gallery

Trays for keeping products

Product exposed to direct solar

radiation

Solar dryer experimental setup

model

Actual experimental setup

developed at IIT guwahati

Previous

Next