Prof S. Senthilvelan Research Group

Department

of Mechanical Engineering | IIT Guwahati

Feasibility

Evaluation of Powder Metallurgy Connecting Rod for Automobile Application

Funding agency Department of Science and

Technology (DST), Govt. of India

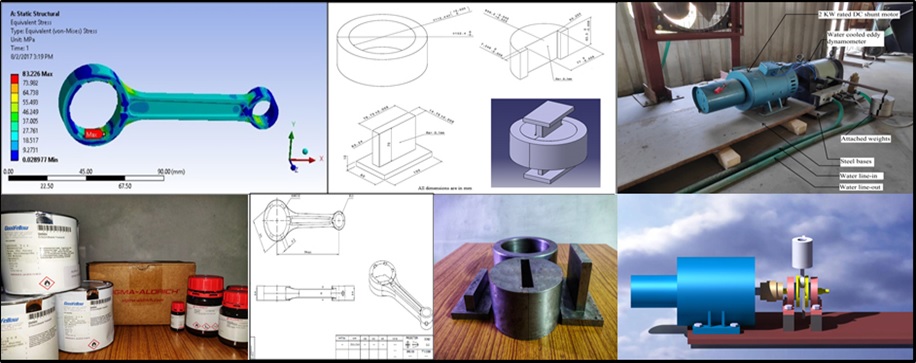

About the project

Connecting rod is

used in the internal combustion engines to transmit the thrust of the

piston to the crankshaft. Connecting rod is subjected

to millions of repetitive cyclic loadings. It should be strong, rigid as well

as light weight to reduce the inertia forces which are produced when the rod

and piston stop, change directions and start again at the end of each stroke.

The connecting rod must be capable of transmitting axial tension, axial

compression, and bending stresses caused by the thrust and pull on the piston,

and by centrifugal force without bending or twisting.

Most of the automotive

manufacturers across the world except our country have switched from forged

steel connecting rods to powder metal(PM) connecting

rods. PM connecting rods do not require additional machining hence they are

preferred over forged connecting rod in spite of increased raw material cost.

The major hesitation in utilizing powder metallurgy connecting rods over

conventional forged connecting rod in our country is non

availability of test data. This project intends to design, develop and

evaluate the efficiency, service life and modes of failure of powder metallurgy

connecting rods.

Current requirements One Regular PhD

Student

Room No.: C-306, Department of

Mechanical Engineering

Indian Institute of Technology Guwahati,

Assam - 781039

Scroll

to Top