Dr. Thiyam Tamphasana Devi

Education

PhD (Indian Institute of Technology Guwahati, Guwahati)

M-Tech (National Institute of

Technology, Nagpur), 2008-2010.

B.E (G. H. Raisoni College of

Engineering, Nagpur), 2003-2007.

Award/Medal/Certificate

Young Environmentalist Award 2011 International Congress of Environmental Research 2011.

Kamakshi Gold Medal for Young Geospatial

Scientist 2010 for best paper in Geospatial world

forum, 2011.

Academic Excellence prize for highest grade in M-tech,

2010.

Certificate for 1st class

with Distinction in B.E, 2007.

Area of research interest

Turbulent flow

CFD simulation

Application RS & GIS in

water resources

Design of water distribution

systems

Ph D Thesis

"Design of Unbaffled Stirred Tank with Concave Blade Impeller"

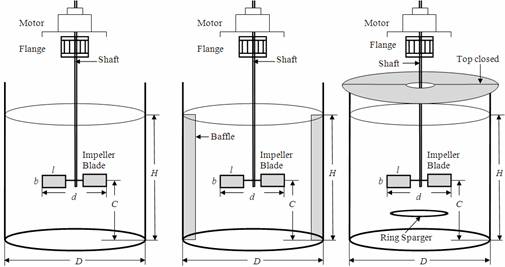

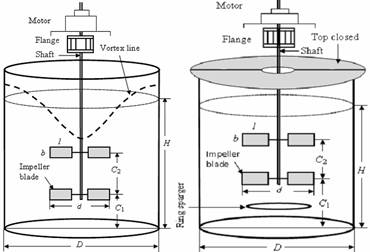

Abstract: The wide applicability of mechanically stirred tanks in industry demands a comprehensive understanding of hydrodynamics controlling the performance of these fundamental units. Standard Rushton impellers in baffled are widely used in mechanically agitated gas-liquid reactors because of the high dispersion efficiency and its flexibility of operation. However, unbaffled tanks are used in many industrial stirred tank systems where the presence of baffles is undesirable. Both experimental investigations and computational studies to analyze the fluid flow hydrodynamics which often showing good potential for industrial use of such type of stirred tanks. Baffles are usually omitted in the case of very viscous fluids, where they, giving rise to dead zones, would actually worsen the mixer performance, and where vortex formation is inhibited by the low rotational speed and by the high friction on the cylindrical wall. Unbaffled tanks are also advisable in crystallizers, where the presence of baffles may promote the particle attrition phenomenon. Unbaffled tanks give rise to higher fluid particle mass transfer rates for a given power consumption, which may be desirable in a number of processes. Regarding Rusthon impeller, several researchers argue its inferior efficiency as compared with other types of impeller. Compared to the Rushton impeller, Concave blade impellers were reported to provide at least the same gas handling capacity, equivalent fluid homogenization performance, similar gas holdup characteristics and less torque fluctuations. Impeller position (impeller clearance depth, C, when single impeller is used and bottom impeller clearance depth, C1 and impeller spacing, C2 when dual impeller is used) should be the major concern geometric parameter in impeller driven stirred system apart from other affecting parameters as the flow pattern generated inside the vessel is dependent on it. Not only the flow pattern but also the purpose of stirred tank is also dependent on it. Compared with single impeller, dual combination has more advantages, such as efficient gas distribution, longer gas phase residence time, increased gas hold-up, superior liquid flow characteristics and lower power consumption per impeller. The aim of this research is to establish the design criteria for concave blade impeller stirred unbaffled tank. This was accomplished through experimentation on unbaffled stirred tank in single and dual impeller with and without sparging system in present study. The influence of impeller diameter (ratio of d/D is taken as 0.2, 0.3 & 0.4), impeller clearance depth (ratio of C/D is taken from 0.3 to 0.9 with 0.1 interval for single impeller and C1/D of 0.15 to 0.85 with 0.05 interval for dual impeller) and spacing between two impeller (C2/D of 0.2 to 0.8) are studied for the governing process dynamics at various impeller rotational speed (N=100 to 1200rpm). Computational fluid dynamics (CFD) has been also used to assess the impact of different cases. Modified drag law considering turbulence nature of flow and degassing boundary condition was applied on the top surface of the tank (by developing user defined function). In numerical modeling, turbulence model was extended by using more advanced turbulence model (Large Eddy Simulation) in order to capture more realistic turbulent flow nature inside the stirred tank. Dimensionless correlations were created from corrected experimental data to act as a guide for future production scale stirred tank design. The methods for correcting experimental data developed in this research have proven to be accurate and useful. Furthermore, the correlations found from the corrected experimental data in this study are of great benefit in the design of production scale stirred tank. Another key aspect of the present work is establishing the stable flow pattern regime in unbaffled stirred tank with dual concave blade impeller. The stable flow regime is generally found in available literature for Rusthon impeller driven stirred tank. The stable flow regime has a profound effect on process dynamic governing the system. Experiments and numerical simulation done in the present work has shown that the optimal systems can be referred to the stable flow regime. The comparative experiments of the unbaffled Concave blade system with baffled and Rushton impeller system has shown that higher mass transfer is produced by baffled system but consumes significant power than the unbaffled system. So, overall performance is found better by unbaffled system based on mass transfer rate and power consumption when the reduction of power consumption is a priority. Better mass transfer rate and lower power consumption is produced by Concave blade system as compared with Rushton type impeller system.

Graphical Results

Scale up criteria for kc at different C/D.

Parity plot of Power Number correlation for Unbaffled Stirred Tanks

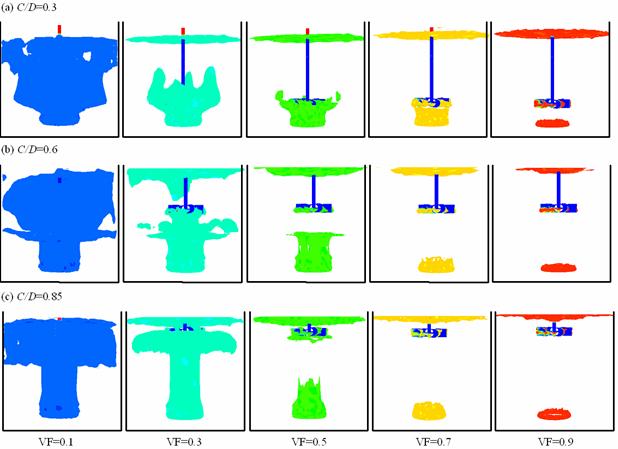

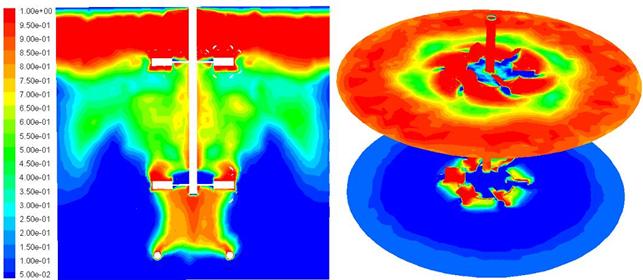

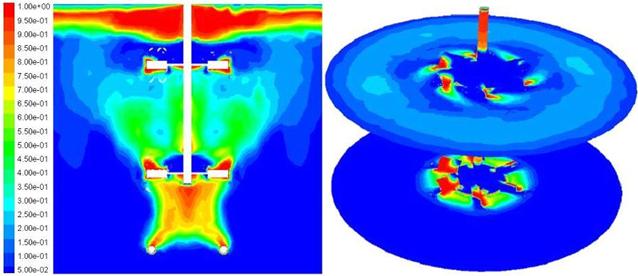

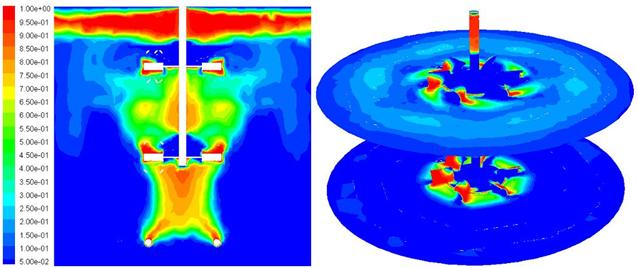

Distribution of different iso-value of gas volume fraction for (a) C/D=0.3 (b) C/D=0.6 and (c) C/D=0.85

Optimal configurations of C1 and C2 based on KLa20

|

Sl. No. |

C1 |

C2 |

KLa20 at 500 rpm |

Remarks on optimal |

|

1 |

0.15D |

0.48D |

0.006816 |

Local |

|

2 |

0.2D |

0.48D |

0.004235 |

Local |

|

2 |

0.25D |

0.38D |

0.007339 |

Highest KLa20 (global) |

|

4 |

0.3D |

0.48D |

0.004134 |

Local |

|

5 |

0.4D |

0.4D |

0.004563 |

Local |

(a) C1=0.25D, C2=0.4D

(b) C1=0.3D,C2=0.4D

(c) C1=0.35D,C2=0.45D

(d) C1=0.4D,C2=0.4D

(e) C1=0.45D,C2=0.4D

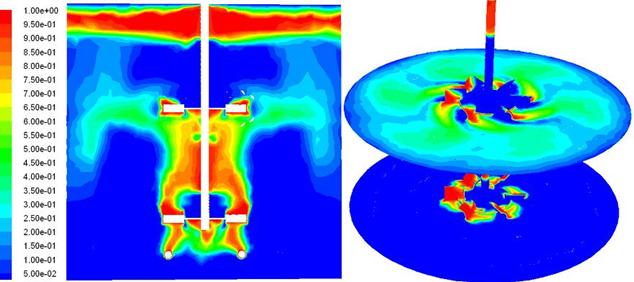

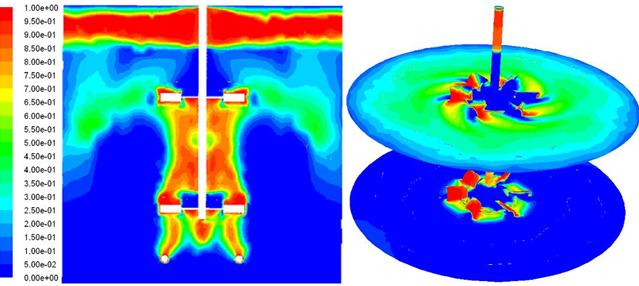

Gas volume fraction of different C1 and C2 configuration at mid plane of the tank (y=0) (left) and at impeller planes (right).

Publications

Journal

Accepted/ Published

Thiyam Tamphasana Devi and Bimlesh Kumar - Scale up Criteria for Dual Stirred Gas-liquid Unbaffled Stirred tank with Concave Blade Impeller, The Korean Journal of Chemical Engineering, Springer, (Accepted for Publication). [IF = 1.241]

Thiyam Tamphasana Devi and Bimlesh Kumar - Design of Gas-liquid Stirred tank with Curved Blade Impeller, Journal of Engineering Physics and Thermophysics, Springer, (Accepted for Publication).

Thiyam Tamphasana Devi and Bimlesh Kumar - Effect of Superficial gas velocity on Process Dynamics in Bioreactors, Thermophysics and Aeromechanics, Springer, (Accepted for Publication) [IF = 0.304]

Thiyam Tamphasana Devi and Bimlesh Kumar - Large Eddy Simulation of Turbulent Flow in Stirred tank with Curved Blade Impeller, Journal of Engineering Thermophysics, Springer, (Accepted for Publication). [IF = 0.522]

Thiyam Tamphasana Devi and Bimlesh Kumar - Comparison of Flow Patterns of Dual Rushton with CD-6 impeller, Theoretical Foundations of Chemical Engineering, Springer, 47, 4, 410-421, 2013. [IF = 0.376]

Thiyam Tamphasana Devi and Bimlesh Kumar - CFD Simulation of Flow Patterns in Dual Impeller Stirred Tank, International Journal of Modeling and Simulation, 33, 2, 2013.

Thiyam Tamphasana Devi and Bimlesh Kumar - CFD Simulation of Flow Patterns in Unbaffled Stirred Tank with CD-6 Impeller, Chemical Industry and Chemical Engineering Quarterly, 18, 4, 535-546, 2012. [IF = 0.61]

Bimlesh Kumar and Thiyam Tamphasana Devi - Microscale of Turbulence and Oxygen Transfer in Surface Aerator, Journal of Environmental Research and Development, 6, 3, 569-574, 2012. [IF = 0.157]

Thiyam Tamphasana Devi and Bimlesh Kumar - Turbulent Modeling of Stirred Tank with CD-6 Impeller, Advances and Applications in Fluid Mechanics, 10, 2, 141-155 2011.

Thiyam Tamphasana Devi, Banoth Malsur and Bimlesh Kumar -Stirred Tank with Arrowhead Impeller- Influence of Submergence Depth on Power Consumption, Chemical Engineering Research Bulletin, 15, 1, 45-47, 2011.

Thiyam Tamphasana Devi, Annu Priya Sinha, Meena Thakre and Bimlesh Kumar - Impeller Submergence Depth for Stirred Tanks, Bulletin of Chemical Reaction Engineering & Catalysis, 6, 2, 122-127, 2011.

Thiyam Tamphasana Devi and Bimlesh Kumar - Analyzing Flow Hydrodynamics in Stirred Tank with CD-6 and Rushton Impeller, International Review of Chemical Engineering, 3, 4, 440-448, 2011

Bimlesh Kumar and Thiyam Tamphasana Devi -Impeller Submergence Depth on Power Consumption of Mixing Tank, International Proceedings of Chemical, Biological and Environmental Engineering, 4, 76-78, 2011

Bimlesh Kumar, Thiyam Tamphasana Devi, Ajey Kumar Patel and Ankit Bhatla-Optimal configuration for power consumption in baffled surface aeration tanks, Bulletin of Chemical Reaction Engineering & Catalysis, 5, 2, 87-93, 2010

Conference / Workshop

Based on MTech Work

Thiyam Tamphasana Devi, Yashwant B. Katpatal-Estimation of Infiltration Rate by SCS-CN and CWC method using Satellite Data: A case study of Bhandara District, Maharastra, International Conference on Sustainable Water Resource Management and Treatment Technologies, Water 2011, Jan 19-22, 2011, IWA/NEERI, Nagpur, India.

Thiyam Tamphasana Devi and Y.B.Katpatal -Identification of Infiltration potential Zones through overlay analysis using reservoir frequencies, spreads and other parameters Geospatial World Forum, January 18-21, 2011, Hydrabad, Andra Pradesh, India. (Kamakshi Gold Medal for Young Geospatial Scientist 2010 Award for best paper).

Thiyam Tamphasana Devi-Intelligent Transport system in GIS environment National Round Table Technical Meet, October 11-13, 2010, 62-65, Indian Institute of Technology, Guwahati, Assam, India.

Thiyam Tamphasana Devi and Yashwant B. Katpatal- Surface runoff depth by SCS curve number method integrated with satellite image and GIS techniques, International Conference on Environmentally Sustainable Urban Ecosystems, February 24-26, 2012; pp90, Department of Civil Engineering, Indian Institute of Technology (IITG), Guwahati, Assam, India.

Based on PhD Work

Bimlesh Kumar and Thiyam Tamphasana Devi -Impeller Submergence Depth on Power Consumption of Mixing Tank International Conference on Environmental Science and Development, ICESD 2011, January 7-9, 2011, Mumbai, 76-78.

Thiyam Tamphasana Devi, B. Malsur and Bimlesh Kumar-Optimal Impeller Submergence Depth for Stirred Tank International Conference on Thermal Energy and Environment (INCOTEE, 2011), 620-623, March 24-26, 7-9, 2011, Kalasalingam University, Anand Nagar, Tamilnadu, India.

Thiyam Tamphasana Devi and Bimlesh Kumar- Power Consumption by different types of impellers used in stirred tanks: A literature review and an introduction to CFD National Conference on WATER, ENERGY AND BIODIVERSITY-with Special reference to North-East Region, August 20-22, 2011, Agartala, Tripura, India.

Thiyam Tamphasana Devi and Bimlesh Kumar- Investigations of mixing in mechanically stirred tank: Comparison of CD-6 impeller and Rushton turbine National Conference on Recent Advances in Civil Engineering, October 14-16, 2011, IT-BHU, India.

Thiyam Tamphasana Devi and Bimlesh Kumar- Application of standard k-ε turbulence model for designing of stirred tanks 4th International Congress of Environmental Research, December 15-17, 2011, Sardar Vallabhbhai National Institute of Technology (SVNIT), Surat, India.

Thiyam Tamphasana Devi and Bimlesh Kumar- Turbulent Dissipation Rates in a Baffled Stirred Tank of Rusthon Turbine 14th Asia Pacific Confederation of Chemical Engineering, February 21-24, 2012, Singapore.

Thiyam Tamphasana Devi and Bimlesh Kumar- CFD simulation of flow patterns in Dual Impeller Stirred Tank, World Congress on Biotechnology-2012, May 4-6, 2012, Hyderabad, India.

Thiyam Tamphasana Devi and Bimlesh Kumar- Quantifying multiphase characteristics in Double impeller stirred tank, National Conference on Frontiers in Chemical Sciences (FICS) -2012, December 03-04, 2012, Indian Institute of Technology Guwahati, Guwahati.